Burton EMS Work Study Program Cultivates Future Tech Leaders on the Gogebic Range

March 7, 2024 Leave a comment

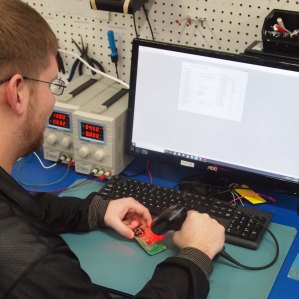

Ironwood, MI – Burton EMS sought to bring industry and education together in collaboration when they created their work-study program. The program offers a comprehensive overview of the electronic manufacturing services sector, providing students with hands-on experience in various aspects of the industry, from design and prototyping to production and quality control. Burton EMS offers the initiative to complement students’ academic learning and create an understanding of the practical applications of their studies, encouraging a passion for innovation, leadership, and engineering.

Senior, Giovanni Lauzon, valedictorian of the class of 2024 at Luther L Wright High School in Ironwood, MI, participated in Burton’s work-study program this year. Sharing his experience, Lauzon remarked, “Being a part of the Burton EMS work-study program has been rewarding for me. It enabled me to apply my knowledge in real-world situations. The hands-on experience and understanding I’ve acquired will be valuable in my future career.”

Lauzon plans to continue his education at Michigan Tech or Gogebic Community College, majoring in computer science. He will utilize the technical knowledge he received at Burton EMS in school and his future career.

As students in the area face career choices in industries demanding advanced knowledge in electronics, programming, and computers, cultivating an early interest in technology is critical to fostering the skills they need to compete in tomorrow’s workforce. The success of students like Lauzon is a testament to the viability of the program.

Gary Burnett, Chief Operating Officer of Burton EMS, echoed that sentiment, “The work-study program at Burton EMS is crucial in creating leaders in the industry who will ensure the continued vitality of technology and manufacturing industries on the Gogebic Range. We’re very proud of Giovanni’s dedication and achievements, and we look forward to seeing more students follow in his footsteps.”

If you know a student who would make a good candidate for the Burton EMS work-study program, email hr@burtonems.com for details on criteria, specifics, and applying.

Products with complex test requirements and legacy products often create challenges in outsourced manufacturing. Are the latest bench test procedures in place? Are legacy components creating unacceptable fallout levels? Are multiple tests being performed in the correct sequence? Is enforced routing in place to ensure repaired assemblies complete all retest steps? The team at Burton Industries wanted to automate their processes to the point where the answers to these questions was always “yes.” In early 2019, Burton Industries’ Test Engineering and IT departments teamed up to develop test software that enhances the test team’s ability to support customers with complex test requirements and/or legacy products.

Products with complex test requirements and legacy products often create challenges in outsourced manufacturing. Are the latest bench test procedures in place? Are legacy components creating unacceptable fallout levels? Are multiple tests being performed in the correct sequence? Is enforced routing in place to ensure repaired assemblies complete all retest steps? The team at Burton Industries wanted to automate their processes to the point where the answers to these questions was always “yes.” In early 2019, Burton Industries’ Test Engineering and IT departments teamed up to develop test software that enhances the test team’s ability to support customers with complex test requirements and/or legacy products.